Willow unitized façade system

A new generation of timber façade systems - Pilefaçade

The building sector remains one of the largest contributors to carbon emissions in Europe. As demands for climate-conscious solutions grow, the Pilefaçade project offers a visionary shift toward regenerative construction – by embracing fast-growing willow as the foundation of a scalable, hybrid unitized curtain wall system.

Pilefaçade is a low-carbon, hybrid unitized curtain wall system, replacing aluminum with willow and using recycled aluminum caps for weather protection. It can save up to 150 kg CO₂e/m² FSA, reducing carbon footprint and enabling fast, cost-effective on-site assembly.

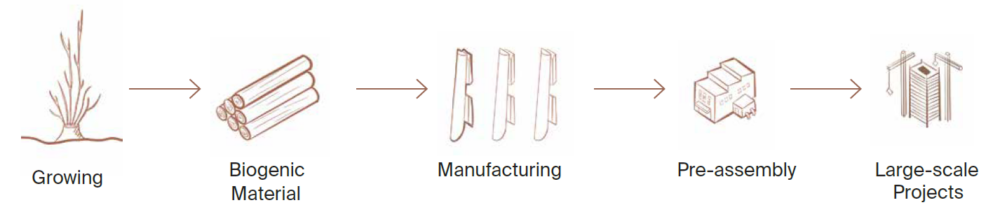

From fast-growing willow to scalable façade system

Pilefaçade explores using willow, a fast-growing, carbon-absorbing plant, to create a prefabricated façade system as a scalable, low-emission alternative to current building systems.

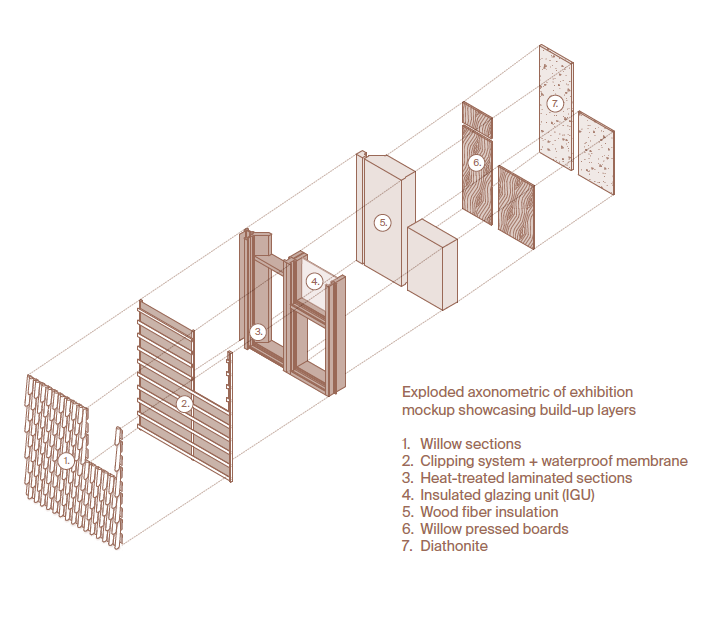

The system incorporates biogenic materials, primarily willow, replacing high-carbon materials like aluminum. It uses laminated willow for load-bearing frames, thin branches for rainscreen cladding, and pressed panels from by-products.

This hybrid design combines the aesthetic and thermal benefits of wood with the stability of recycled aluminum caps, enabling faster installation, improved insulation, durability, and a reduced CO₂ footprint.

Insulation panels

Willow enhances thermal performance, improving energy efficiency.

Load-bearing frames

Laminated willow provides a strong, sustainable alternative to metals.

Acoustic panels

Willow’s density helps with soundproofing.

Interior wall linings

Willow regulates humidity and improves thermal insulation.

Exterior cladding

Willow’s weather-resistant properties make it ideal for durable, low-maintenance cladding.

Staticus

pre manufactured assembly design and production

Schmidt Hammer Lassen

façade component design, research and development

pilebyg

raw materials growing, process knowledge

moow.

research testing, development and production of willow-based materials

Learn more