Design for Manufacturing (DfM)

The façade industry faces growing demands to deliver projects that are sustainable, efficient, and cost-effective. At Staticus, we address this with our Design for Manufacturing (DfM) system, which simplifies façade elements for easier production and assembly while still allowing for customised architectural design.

This system enables greater standardisation of façade components, significantly reducing waste, embodied carbon, and energy use during manufacturing. At the same time, it improves efficiency, lowers costs, and ensures faster delivery of complex, large-scale projects.

Designing façades for production efficiency

DfM is Staticus’ own aluminium unitised façade system, developed to align design with the most efficient manufacturing capacities. It was created through a close iterative process between our engineering, technology, and production teams, with a clear focus on waste reduction, efficiency, and sustainability.

By simplifying and optimising the internal panel structure, we enable streamlined manufacturing while retaining full flexibility for bespoke exterior designs. The result is a system that benefits clients through cost-effectiveness, faster delivery, and lower environmental impact.

Key benefits of our DfM façade system

-

Optimised manufacturing

Standardised aluminium profiles with 90° screw-joined connections simplify production, eliminating corner inserts and cutting fabrication time by up to 20%. -

Lower environmental footprint

Reduced material usage help cut embodied carbon. -

Flexible design freedom

Bespoke finishes and complex façade geometries remain possible while production stays efficient. -

Faster delivery of complex projects

Seamless integration between design, production, and assembly ensures shorter lead times. -

Future-ready sustainability

DfM aligns with design for disassembly principles, enabling easier material recovery at end-of-life.

Performance of Design for Manufacturing (DfM) façade system

Our DfM aluminium façade system has undergone extensive testing at VINCI Technology Centre in the UK, confirming compliance with demanding performance standards, including air permeability, water tightness, wind and impact resistance.

The system has been refined for structural silicone-glazed façades and adapted to specific architectural requirements such as curved corners and sinus-shaped finishes. Simplified profile connections and exclusive use of 3D models across the design and production stages further enhance efficiency and precision.

| Test | Standard | Classification / Declared value |

|---|---|---|

| Air permeability | EN 12152 | AE / 900 Pa |

| Watertightness | EN 12154 / CWCT | RE / 1200 Pa 600 Pa dynamic |

| Wind resistance | EN 13116 | ±1500 Pa serviceability ±2250 Pa safety |

| Impact resistance | EN 14019 | E5 & I3 |

Separatorn 1

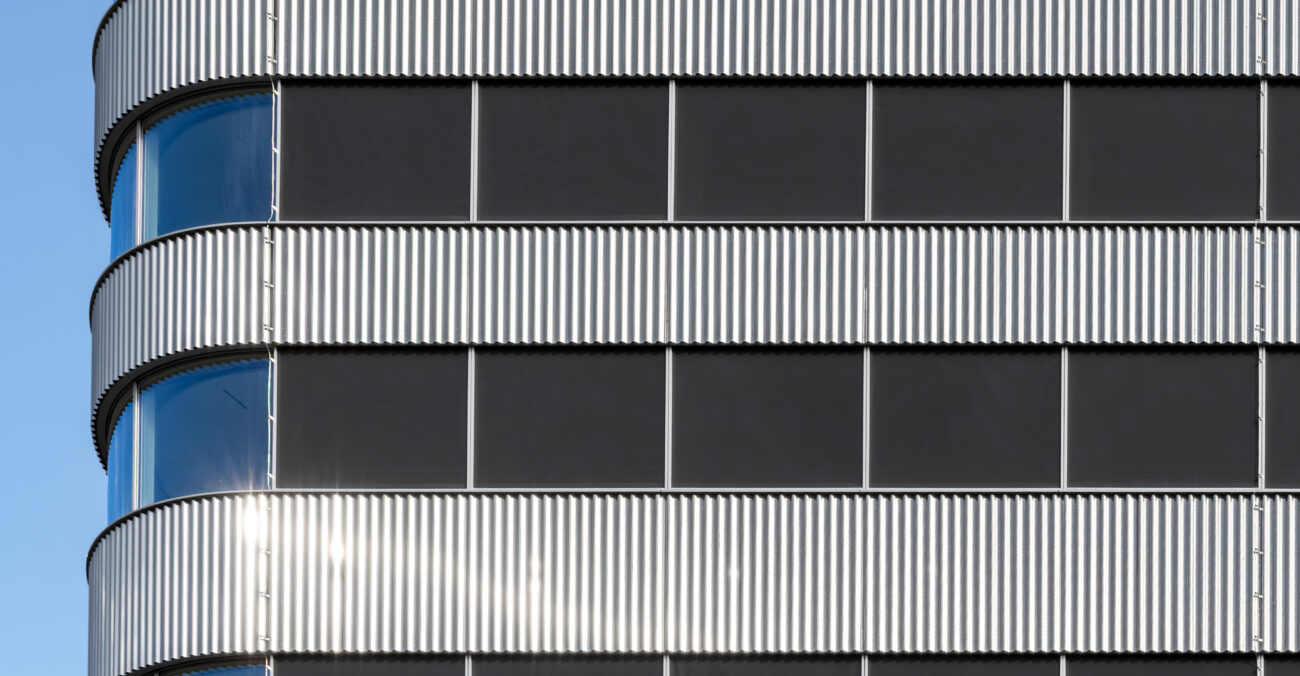

The Separatorn 1 (S1) project in Stockholm marks Staticus’ first deployment of our in-house aluminium façade system based on Design for Manufacturing (DfM) principles.

This 12-storey office and innovation centre features a 7,037 m² unitised façade with unique sinus-shaped stainless steel finishes and curved corners. Developed over three years of R&D, the system was tailored exclusively for S1, tested successfully at VINCI Technology Centre in the UK, and delivered with improved efficiency, reduced material waste, and greater sustainability through the use of 3D modelling and optimised profiles.Read more.

Separatorn 1, Stockholm. Our first project using the in-house developed aluminium DfM façade system.

Separatorn 1, Stockholm. Our first project using the in-house developed aluminium DfM façade system.

Separatorn 1, Stockholm. Our first project using the in-house developed aluminium DfM façade system.

Separatorn 1, Stockholm. Our first project using the in-house developed aluminium DfM façade system.

Michigan Avenue Tower 2

The Michigan Avenue Tower 2 project in Manchester marks Staticus’ first UK use of our Design for Manufacturing (DfM) system, and the first structurally glazed façade with fins created using this approach. Spanning 14,109 m², the façade integrates zero transom bulkhead details, purge ventilation windows, and advanced fire-safety solutions.

By applying DfM, we will deliver the project more efficiently and sustainably, with production and installation starting in Q1 2025. Read more.

Michigan Avenue Tower 2 façade installation in progress ⟶