Company value chain

Over the past 20+ years, we’ve developed a complete value chain that we manage in-house - ensuring full control to protect your investment and your timeline.

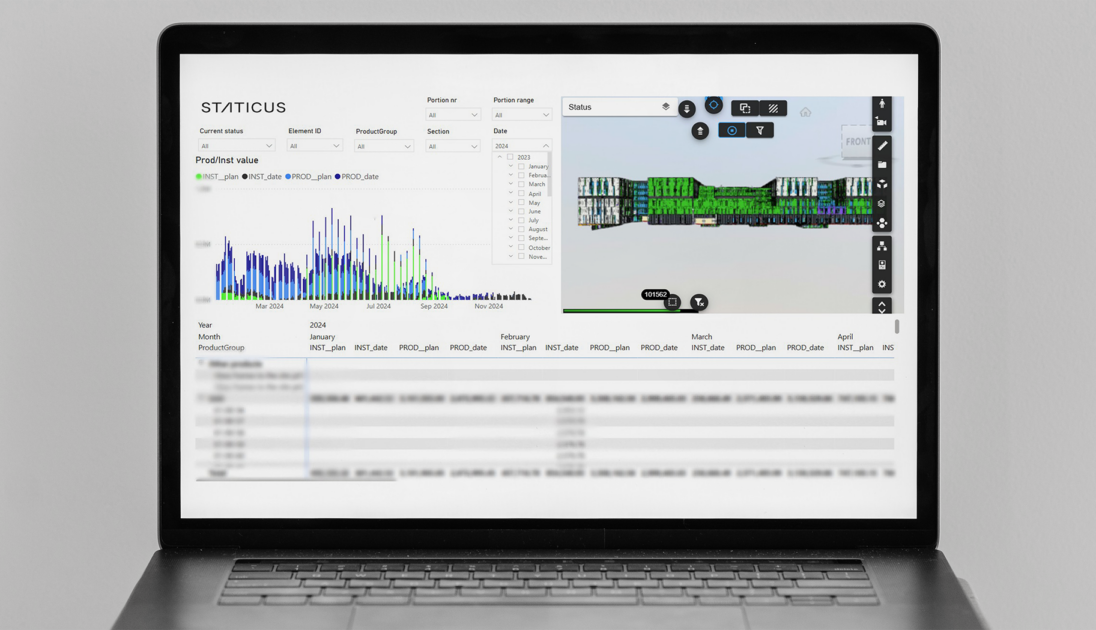

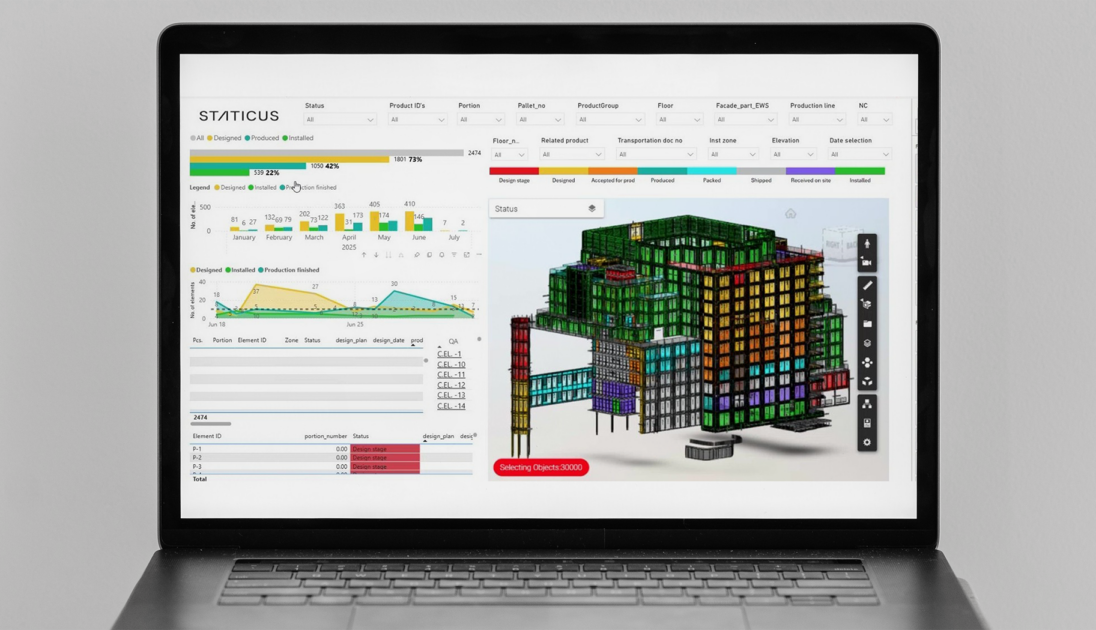

Staticus, a family-owned company with over two decades of sustainable growth, brings a long-term perspective and a clear focus on delivering projects on time and on budget – for both our clients and our company. We manage every stage of façade delivery – from design and engineering to manufacturing, installation, and aftercare – with one in-house team. Our focus is to deliver transparency, by XD reporting tool, technically advanced solution by our experienced cross-functional teams.

The project is our product

We don’t simply build a façade for you, we develop a bespoke project. We do this by offering tailored innovation and critical inputs, a process which begins by finding the right design to fit the needs of the building and the vision of the architect. Then, using our agility and strength in digitalization, we set up the tools, teams and processes required for that project. In total, we have 100 in-house engineers, who combine their deep know-how in engineering and architecture to consult closely and provide critical inputs at the earliest moment. The end result is a fully customised value chain, with R&D and design tailored to fit the exact requirements of the façade needed.

Project stages

01Concept design and consulting

Staticus delivers tailored and innovative solutions designed to fully realise the concept of the architect and the client. To do this we engage early, developing concept solutions with all stakeholders concept design and consulting closely with the client. This process includes:

- Early-stage consulting (early involvement allows us to design energy-efficient façades, choose suitable recycled materials, and optimize) panelization,

- Concept design development,

- Advice on the technical feasibility of the project

- Customized project solutions,

- budgeting and cost planning.

We also develop prototypes as part of the concept design process. These allow project stakeholders to analyse façades on a small-scale physical model. It also enables our engineers to evaluate design risks.

The final component of our concept design work is check-ups and feasibility assessments, which allow us to deliver optimal façade solutions.

02Design development

The design development phase consists of working through every design question and problem solving to ensure that the project goes smoothly. This includes feasibility consulting, pre-construction services, structural and physical calculations, advanced 3D modelling, parametric design, BIM, workshop design, installation drawings, and as-builds.

For façade project design, coordination and production, Building Information Modelling (BIM) is a key tool used by our teams. BIM models allow us to efficiently manage the large amounts of information in each project, effectively interact with other parties, easily monitor a project’s schedule and costs, and anticipate and mitigate potential risks.

When it comes to the project management of the design development stage, Staticus’ experienced team offers 3 important benefits. Firstly, we have international experience. We have operated in more than 15 countries so far, and our team features highly-skilled team specialists from around the globe to work. Secondly, we have developed seamless processes for coordinating large teams – by leveraging project management methodologies such as PMP, Prince and Agile, 7-9 key leaders can effectively manage the work of more than 150 team members. And thirdly, we use agile methodology, short production cycles, and clearly defined responsibilities to deliver a solution-oriented approach to every project.

03Mock-ups and testing

Mock-ups allow investors, contractors and architects to assess the façade’s appearance, the quality of materials, the colour scheme, the chosen connectors, and the construction itself.

Staticus provides different types of mockups and testing options to cover both frequent and niche use-cases. These options include:

- Material compatibility. These small-scale mock-ups consist of one or two components and are used for performing ageing tests in a climatic chamber.

- Material sampling. These small-scale mock-ups feature two or more components and are used to introduce the technical and visual solutions being proposed.

- 3D prints. These small-scale mock-ups are used to introduce the technical solutions being proposed, especially new systems.

- Visual mock-ups. These mock-ups are real-size and are produced to confirm the proposed design with the project stakeholders.

- Performance mock-ups (PMU). These are created to ensure the quality of the façade system and to check its compatibility with specific façade standards. Performance mock-ups enable us to ensure the façade’s structural stability, evaluate and validate the façade design, identify any problem areas, and then rectify any flaws. Our mock-ups are tested by Rosenheim University specialists in Germany and in VINCI Technology Centre, UK.

04Production

With 180,000 m² of unitised façade production capacity annually, 12,000 m² of dedicated production space, and in-house testing facilities, our setup is designed to deliver complex façades with speed, accuracy, and consistency – keeping your project on programme, on spec, and on budget.

Capacity and capabilities:

-

12,050 m² – production area

-

150,000 m² – maximum annual production capacity

-

10-12 – assembly lines (operating in 2 shifts)

-

3 – independent production facilities

-

5-6 – projects produced simultaneously

-

6 – expert groups in programming machinery

This flexible infrastructure enables us to efficiently manage multiple complex projects, adapting production to meet each project’s technical and scheduling requirements.

05Logistics

At Staticus, logistics is not just a support function – it’s a strategic capability. Our in-house team ensures the safe, timely, and sustainable delivery of façade elements to sites across Europe.

Flexible packaging options

We use customised steel stillages and wooden packaging tailored to project dimensions, meeting both local and international transport requirements.

Diverse transport methods

A wide range of transport options – including containers, curtain-sided, and flatbed trailers – are available through a trusted network of 7 logistics partners, enuring reliable and on-time delivery.

Strategic location & environmental efficiency

Our geographical location in Lithuania enables fast regional distribution. We continuously optimise truckloads to reduce emissions and costs, using only EURO 6 compliant vehicles to support environmental goals.

Dedicated logistics centre

To support increased demand and improve operational capacity, we operate a dedicated Logistics Centre located 21 km from our Vilnius headquarters. The site covers a 2.9-hectare plot and includes:

-

Up to 11,000 m² of indoor and 10,700 m² of outdoor storage space

-

Warehousing, back offices, domestic premises, and conference space

-

Facilities for material storage, assembly work, profile preparation, packing, quality control, and storage of completed products

This centre enables greater flexibility and control over delivery planning and storage across all project locations.

06Installation

At Staticus, our goal during installation is to use time on-site as efficiently as possible while maintaining the highest standards of safety and quality.

01. Technology strategy

We tailor installation methods to each project’s needs, ensuring safety and efficiency. Our in-house team selects tools like tower cranes, mini cranes, mobile and truck cranes, monorails, and glazing robots to match site conditions and complexity.

02. Location strategy

We make strategic decisions about insourcing vs. outsourcing based on local labour, health, and safety regulations.

03. Site logistics strategy

We optimise delivery to the site and plan intermediate storage to ensure smooth, timely installation with minimal disruption.

04. Capacity strategy

Our workforce strategy balances project needs with available resources. We deploy skilled H&S-trained personnel from our pool of:

-

80 in-house installers

-

160 outsourced installers

-

2 strategic UK suppliers

-

2 strategic subcontractors in Nordics (DK, NO, SE, FI, ISL)

Dedicated managers

Every project is led by an experienced construction manager who develops a bespoke installation plan and oversees execution from start to finish.

07Warranty and after-warranty

Our involvement doesn’t end with installation. Every Staticus façade includes a service warranty, backed by a dedicated team and regional partners for rapid support across all project locations.

We provide a full spectrum of after-warranty services, from inspections and repairs to long-term maintenance and full façade renovation. Preventive checks help identify issues early, ensuring long-term performance and client peace of mind.

Our expertise covers everything from thermovision and weather testing to the servicing and upgrading of façades, including integrated solar control systems. Read more.