Staticus’ own façade system deployed for first time in Stockholm office development.

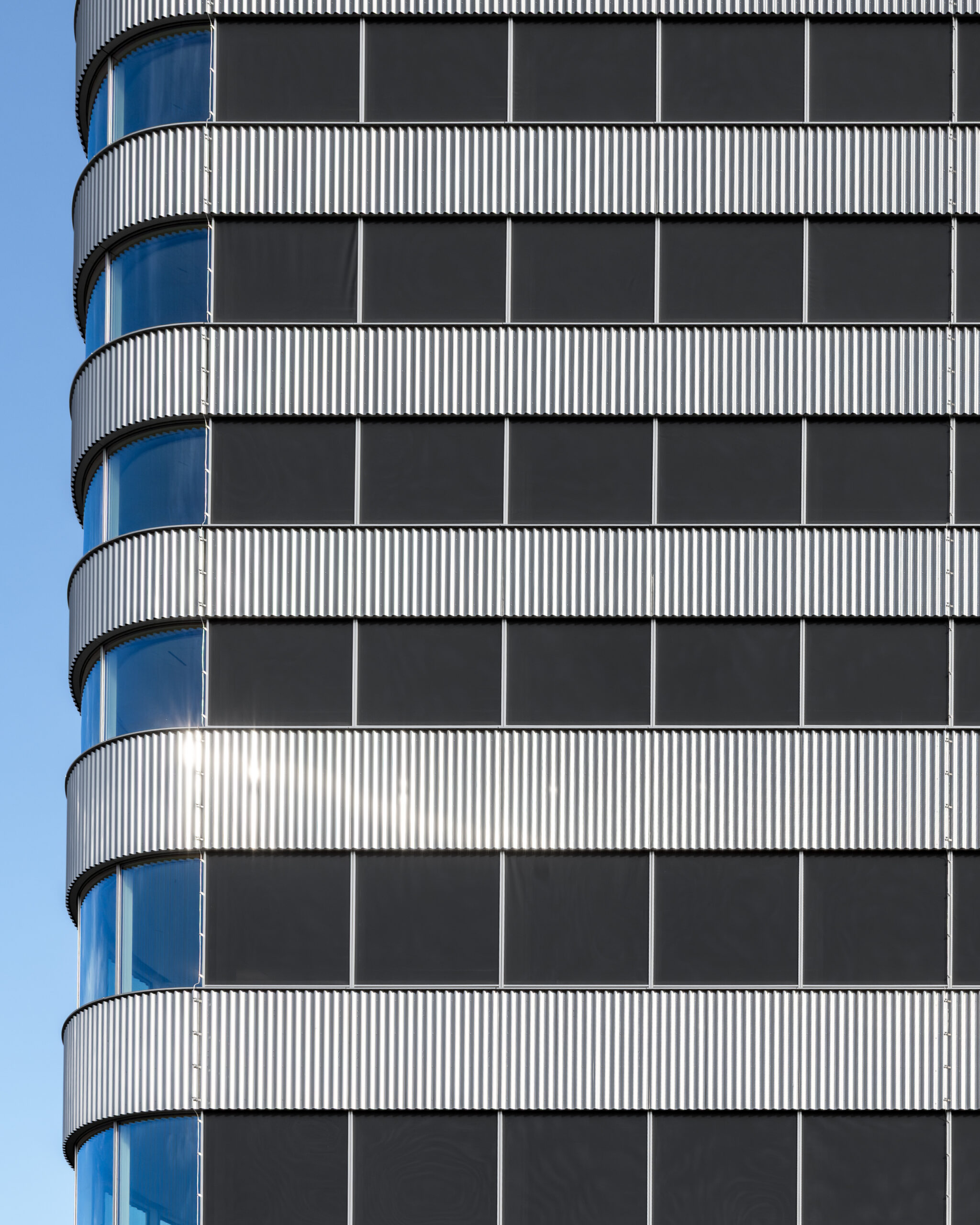

S1 is a 12-storey development in Stockholm that will house offices and an innovation centre. The 7,037 m² façade is unique for its curved corners and sinus-shaped stainless steel finish. S1 also represents a major step for Staticus, as it is the first project based on our aluminium façade system, which has been developed in-house by our R&D team.

S1’s façade has a number of challenging features, including corrugated metal sheet cladding. The elements are large, with standard units at 2.7 m x 3.7 m, and the tallest reaching up to 5.5 m high. Plus, there are two corner elements.

Using our own in-house façade system added an additional level of complexity to this project. We coordinated the production of profiles and gaskets with two different extrusion companies. We also put our façade system through rigorous testing at VINCI Technology Centre in the UK. It passed successfully, achieving the set parameters for acoustics, air, and water permeability with minimal adjustments needed.

This additional complexity was most definitely worth it. Using our in-house system as a foundation, we were able to create specially-tailored profiles exclusively for the S1 project. This tailoring process took more than one year and enabled us to ensure we met the exact needs of the client. Using our own system also brought advantages for us at the production stage. With more control over the value chain, we were able to ensure greater efficiency, with less material waste and energy use. This was enhanced by our exclusive use of 3D models in the design and production phases. Incorporating Design for Manufacturing principles—designing parts, components, or products with a focus on ease of manufacturing and assembly—we were able to produce the façade more efficiently and sustainably.

Our system has been in development since 2021, and deploying it successfully in a project for the first time represents a significant step for us. Main element installation on the S1 project was completed in January, with project finalisation due in Autumn 2024.

Being able to commercialise an innovation we have been working on for three years is a testament to our team’s technical ability, and demonstrates that the new products we are developing meet real market demand. It also highlights the importance of our long-term partnerships. We have worked together with client Skanska Sverige AB on numerous major projects in Sweden. Furthermore, we are partnering with investor Fabege on another innovative project, this time featuring our new Hybrid Unitised Façade (HUF). These close partnerships are characterised by trust, open communication, and shared priorities, which make deploying new innovations possible.