Cancer treatment using proton radiation is an advanced technology, and requires specific facilities. In the case of Norway, these facilities are located in the new clinical building at Radiumhospitalet, Oslo. The façade for this new clinical building, which was designed, produced and installed by Staticus, came with exacting requirements. These included elements that meet EI30 and EI60 fire ratings, explosion-resistant doors, and excellent acoustic performance.

When our team began work on this façade in 2021, their challenge was to meet these specifications while delivering a complex and multi-faceted 20,000m2 façade on a narrow site adjacent to a fully-operational hospital building. In this case study, Design Manager Thomas Fink and Site Manager Andžej Dzikevič explain how we overcame this challenge to deliver a unique, high-specification façade for Norway’s leading cancer treatment centre.

A cutting-edge cancer treatment facility

Radiumhospitalet University Hospital is a specialised cancer research and treatment facility located at Montebello in Oslo. In 2018, the Norwegian government agreed to add a new clinic featuring proton radiation therapy facilities as an extension to the existing hospital.

The proton building of this extension is specifically designed to house three radiation treatment rooms: two for patients and one for research. It features a radiation production and treatment section, which is housed inside a bunker made of solid cast-in-place concrete. The extension also includes an ordinary hospital building with diagnostic imaging, examination rooms, work areas and a bed wing.

Designed by Henning Larsen, the project was developed by HENT AS for Sykehusbygg HF, the Norwegian Hospital Construction Agency.

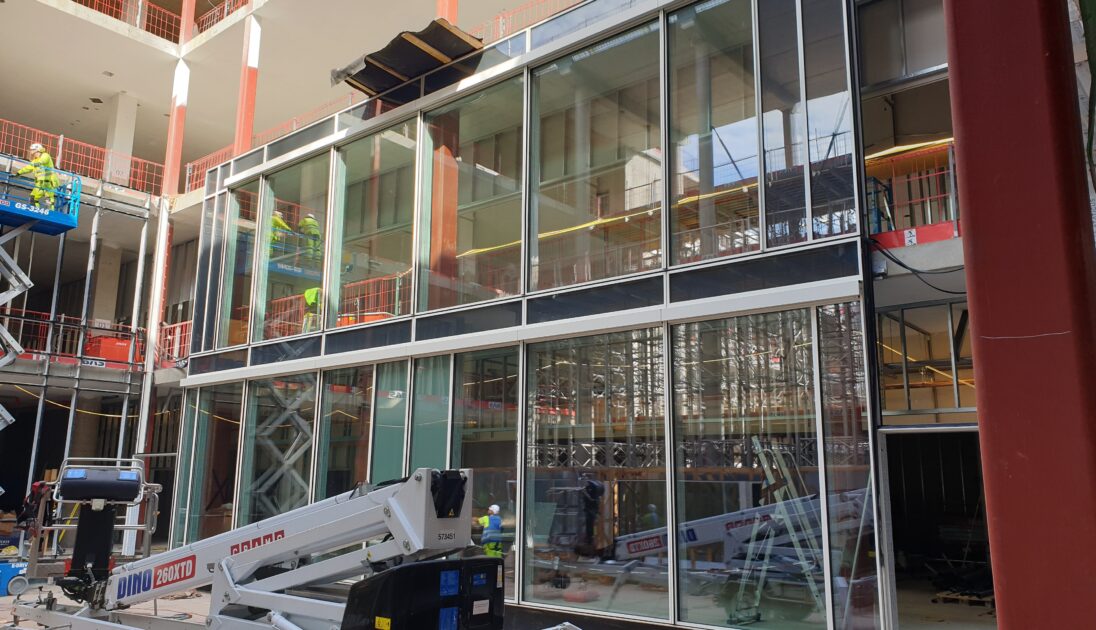

A complex and multi-faceted façade

Staticus’ scope of work for this project was wide-ranging. The project featured two different unitised façade systems, stick façades with and without steel substructures, and three different ventilated façades with different types of cladding and fillings. Our work also included glass roofs, steel-aluminium doors, and ceilings.

In total, we designed, produced and installed:

- 12 100 m² of unitised façade,

- 700 m² of stick façade,

- 1 350 m² of soffits,

- and 5 600 m² of ventilated façade.

- 185 m² of glass roofs,

- and 65 doors.

Different aesthetic requirements

Perhaps the most striking characteristic of this façade is the level of complexity. “For this project, we needed to create unitised façades, stick facades, ventilated façades (with U-glass and with wooden fins), sandwich panels, and glass roofs,” Thomas explains.

“The building has a complex design, and different areas of this new extension have specific functional and aesthetic requirements,” Thomas continues. “For example, the proton bunker features a U-glass façade. The architects chose this design in order to soften the presence of the concrete bunker by creating some kind of transparency.”

“The entrance pavilion to the new clinic has a contrasting aesthetic,” notes Thomas. “It features wooden fins which make the building feel less sterile and more natural, creating a welcoming environment for patients.”

Two unitised façade systems plus ventilated façades and doors

The Staticus team created two different types of unitised façade for Radiumhospitalet. “One was based on a windows system, where the glass panes have been set back to create the look of classical ribbon windows,” explains Thomas. “The second, which was used for the courtyard and bridge, was a standard façade with a flat outer surface.”

“The ventilated façades were designed with 3 different types of cladding and several fillings, and there were 65 different doors required for this project,” Thomas continues. “These doors ranged in material from aluminium to steel, and included fire-rated and non fire-rated doors, and even explosion resistant doors.”

Complex technical infrastructure and site requirements

As with all hospital façade projects, there was a range of technical requirements to take into account, plus some specific site security considerations.

“The building’s extensive technical infrastructure includes pipes, ventilation systems, antennas, cameras, and all types of lighting,” comments Thomas. “Integrating these numerous elements into the façade presented a significant challenge, requiring careful coordination and planning to ensure the façade’s functionality and aesthetic integrity.”

“In terms of the site, the security requirements were at the highest level,” adds Andžej. “The client is a governmental institution, and they hired security specialists, who monitored safety on site, including, for example, which chemicals were being used by contractors.”

“The installation team had extra requirements for this project,” Andžej continues. “There was a lot of additional paperwork which we had to prepare in Norwegian, plus intensive testing of the façade and its assembly.”

Fire safety

When designing and building a façade for a proton bunker that houses high-voltage components, fire safety is paramount. “Transformer rooms, for example, pose a higher fire risk. The façade above these rooms require a fire rating to prevent fires spreading vertically to the patient bedrooms above,” Thomas points out.

Other key fire safety considerations included the prevention of fire spreading because of the close neighbouring buildings, and the need to protect escape routes so that the building can be safely evacuated in the event of a fire.

As a result, some of the façade elements had to meet the strict EI30 and EI60 fire ratings. “EI60 in particular is a rare requirement, and meeting it required ingenuity and careful planning from our team,” says Thomas.

Solving the challenge of fire testing

“One of the main issues was that conducting full-scale fire tests is costly and time-consuming, and would have set the project back in terms of delivery,” explains Thomas.

“The creative and safe solution the team found was to adapt a window system that was already fire-rated. The façade elements were designed so that they meet the required performance characteristics in terms of stability, space-enclosing effect, and thermal insulation. We worked closely with the Institut für Brandschutztechnik und Sicherheitsforschung (IBS) in Austria, who have great experience with façade testing”.

“This approach ensured the façade had the necessary fire level, while the project remained on track in terms of timeframe,” concludes Thomas.

Transformer rooms create unique explosion-resistance requirements

One special consideration for this project was finding suitable solutions for the transformer rooms. “These transformer rooms require explosion-resistant doors, which Staticus had to provide and install,” says Thomas. “Explosion-resistant doors are far from standard in a façade project – in fact, it was the first time the team had managed such a requirement.”

Meeting this requirement meant working in close partnership with suppliers to develop a solution that met the safety standards required. “These doors are designed to remain in place and ensure the safety of hospital workers in the unlikely event of an explosion,” explains Thomas.

High acoustic insulation requirements to ensure patient well-being

A hospital building’s design and performance can directly impact patient well-being, which in turn has an effect on their recovery. One of the most important factors in patient well-being is noise levels, which means acoustic insulation is an important consideration for a hospital façade.

“The client set high requirements for acoustic insulation on this project,” says Thomas. “One section of the new clinical building is next to a busy main road, so effective sound insulation for this area was especially important.”

“This was not simply a question of bolting on additional solutions,” Thomas highlights. “Each acoustic insulation measure we used required careful calculation and coordination with the production and installation teams. That is because each solution added additional weight and created more complexity, potentially impacting production and installation.”

After careful consideration, and consultations with specialist institutes and companies including Anderson Acoustics, suitable solutions were found. “We used special sound-reducing glass in many areas of the façade. We also incorporated heavy elastic foils and inserts into the façade elements to absorb sound. Finally, the façade panels were strategically separated to disrupt the transmission of sound between rooms,” explains Thomas.

Installation on a busy and narrow site

As is often the case with hospital projects, installation was carried out while the existing buildings remained fully operational. Furthermore, the building site was narrow. Plus, there was the added complication of connecting the new facility to the existing building stock.

The Staticus installation team managed these challenges through careful planning and close collaboration, as Andžej explains. “Installing the unitised façade was an intensive job that was completed by two installation teams. The façade elements were stored in two off-site warehouses, so the logistics of transporting them to the site required careful planning and coordination.”

“We also had to plan our daily installation activities with precision and agility,” Andžej continues. “Processes on the site were dynamic, with around 500 workers from different contractors all working at the same time.”

“Overall, this project demonstrated the importance of having flexible and hard working teams – every Staticus employee was motivated and worked collaboratively, and this enabled us to find the right solutions and organise our processes effectively. We have all gained valuable experience working on this project that we can apply to other projects in the future.”

A high-spec hospital façade delivered successfully

Despite the design and installation challenges, the main façade was successfully installed in 2023. Final work is being carried out to complete the project.

Opening this new clinic means patients in Norway can now access advanced cancer treatment in facilities that are safe and that enhance patient well-being.