An aluminium façade system developed by Staticus’ R&D team that is based on Design for Manufacturing (DfM) principles has successfully passed testing at the VINCI laboratory in the UK. The system has been developed inhouse, and then tailored specifically for the Separatorn 1 project in Stockholm. Having successfully tested elements at VINCI Technology Centre in the UK, the team will now produce and install 680 elements of this unique unitized aluminium façade for this 12-storey office complex and innovation centre.

This marks a major milestone in an ongoing R&D project focused on using DfM to reduce the carbon footprint of a façade while maximising cost effectiveness. Reaching this point has only been possible thanks to the support and trust of our long-term partners, Skanska and Fabege AB.

In this article, we explore the significance of this step forward in our R&D activities. We break down:

- what Design for Manufacturing is and why it is important for improving the sustainability of façades,

- how we have developed our new aluminium façade system,

- how it will be used in the Separatorn 1 project,

- and why our long-term partnerships have been so important in facilitating this innovation.

DfM unlocks sustainability and cost effectiveness

Design for Manufacturing (DfM) is the term given to designing parts, components or products with a focus on ease of manufacturing and assembly. By simplifying, optimising and refining a façade’s design in this way, it can be produced more efficiently and sustainably.

“DfM goes directly with sustainability,” explains Staticus CBDO Aulikki Sonntag. “This is an approach that allows a much greater degree of standardisation of façade components. The core of the high-performance panel is optimised for manufacturing and assembly, while still allowing for bespoke design on the outside.”

More standardisation and improved efficiency can result in lower energy and material usage at the production stage, cutting the overall embodied carbon of a façade unit.

Naturally, DfM also brings significant benefits in terms of the cost and timeframe of façade projects.

Producing our own aluminium façade system

Aware of these benefits, in 2021 we embarked on a major R&D project to create our own aluminium profiles for designing and creating an aluminium system. This system is based on DfM principles, and creates a standard toolkit for the core components in a façade while maintaining the flexibility needed to adapt to each project.

“In the end, each project is unique,” Aulikki explains. “However, there are still some core components that can be much more optimised, and DfM makes this optimisation possible.”

By 2022, our system was ready to be deployed on a project for the first time. With the support of General Contractor Skanska and end client Fabege AB, it was agreed that our system would be used for the Separatorn 1 project, in Flemingsberg, Southern Stockholm.

Adapting our system for Separatorn 1

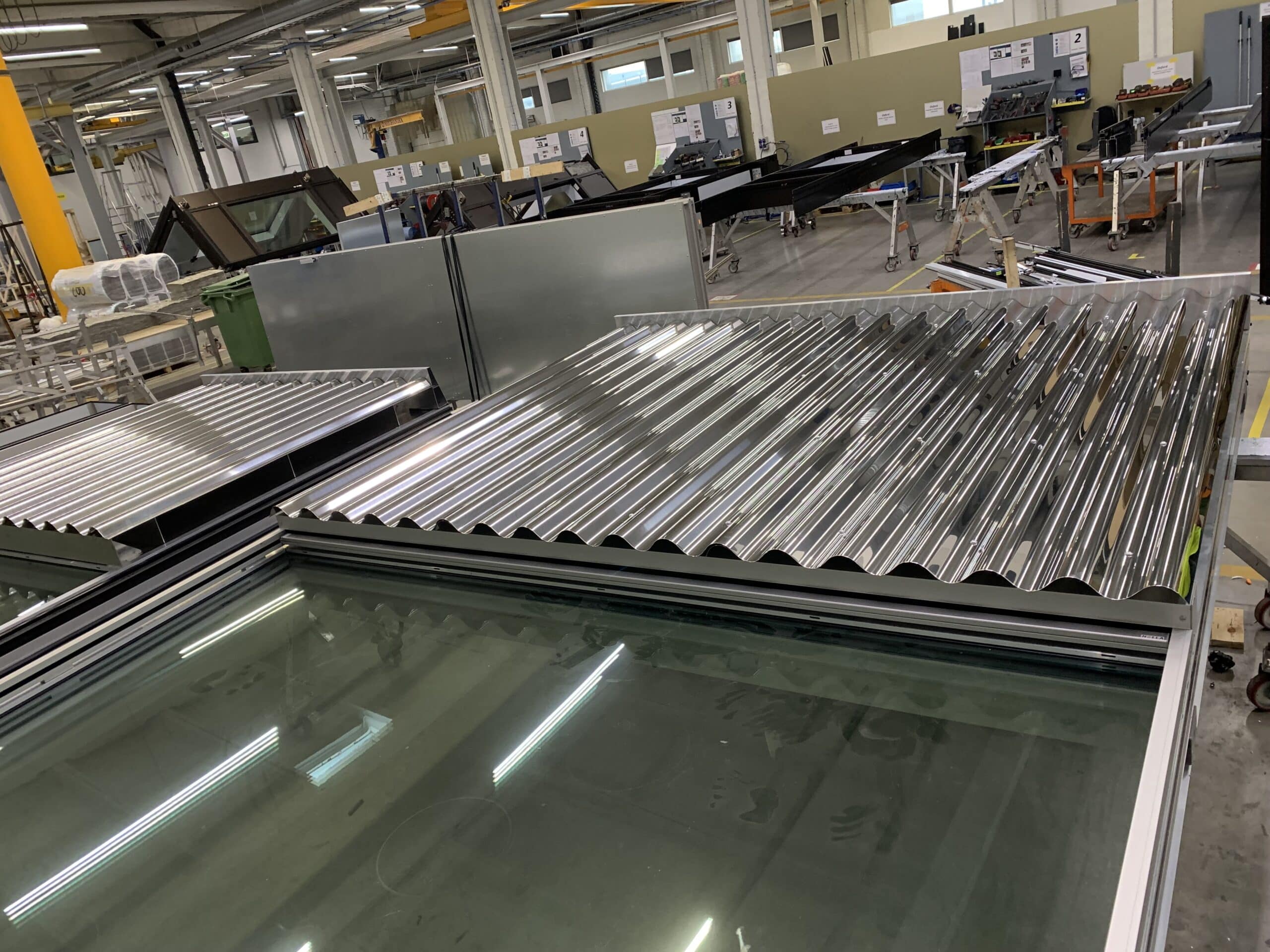

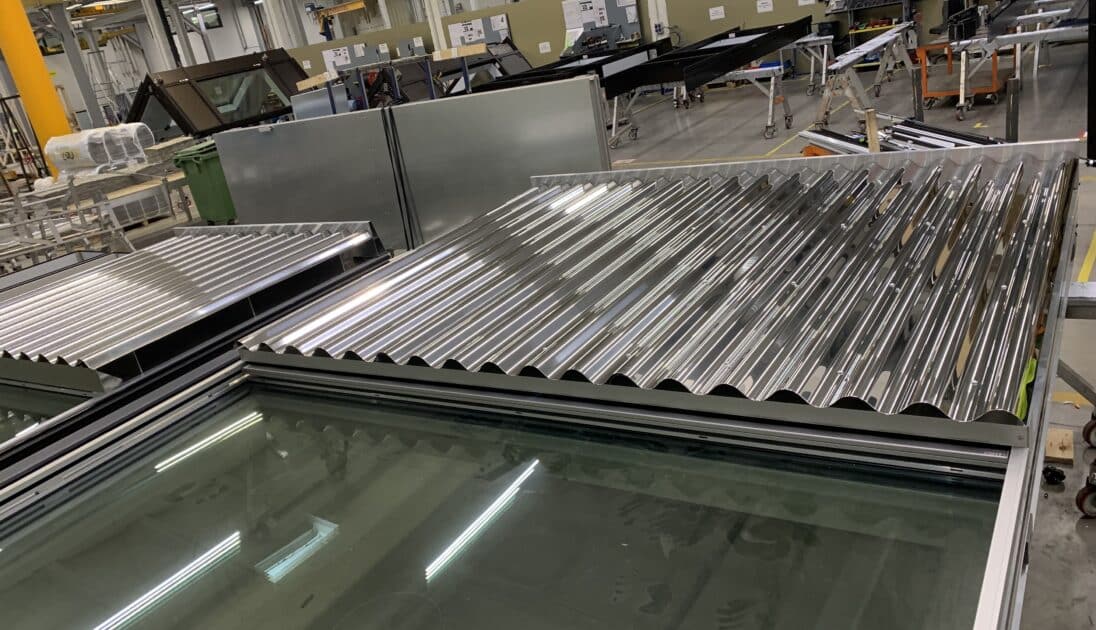

Separatorn 1 is a 30,000 sq. m development that will be home to offices and an innovation centre. Designed by architects Tham & Videgård Arkitekter, the building requires a 7,037 sq. m. unitized aluminium façade. Each façade element will have a sinus-shaped stainless steel finish, and the design is unique for its curved corners. The façade will also feature a custom-made aluminium unitized curtain wall system, a version with cover caps, external roller blinds for sun protection, and corrugated metal sheet cladding.

Adapting our DfM system to meet the specific requirements for Separatorn 1 was a significant technical challenge, says Staticus Head of Concept Design Gedminas Putnikas.

“Even though we had been working on our own aluminium façade system for a long time, it took us about a year to develop the unique concept for Separatorn 1,” Gediminas explains. “The system had to be adapted to make it easy to produce curved corners – these curved corners are one of the main highlights of this project.”

“It was also necessary to deal with the rejection of wide and heavy glazing units, but this is something we do with other systems as well. The system itself has been simplified so that the profiles can be cut and joined at 90 degrees using screws without the need for corner inserts. This makes it easier to manufacture. The result is a unique façade based on our system but specifically adapted for the needs of the Separatorn 1 project.”

We have coordinated the production of profiles and gaskets together with extrusion companies, and all of the profiles have been developed exclusively for this project.

Another notable feature is the exclusive use of 3D models during design and production. Last month, Staticus successfully completed the production stage of a project solely using 3D models for the first time, and Separatorn is building on this experience. “Everything has been prepared in 3D drawings,” says Linas Bacvinka, Senior Design Engineer. “And these 3D models are for all stages of design and production.”

Successful testing at VINCI in the UK

Staticus carried out air and water infiltration tests for the façade system inhouse. We then developed, produced and tested a fully working representative facade area of this system for the project, which has been put through rigorous testing.

The tests were carried out in VINCI Technology Centre in the UK, and were passed successfully. “The parameters set for acoustics, air and water permeability have been achieved with minimal adjustments or corrections needed,” explains Gediminas. “As this is our first system of this kind, passing these tests is an important achievement.”

One notable aspect of the testing was the size of the PMU mock-up. “The mock-up has a total height of 9 metres,” comments Linas. “According to the staff at VINCI, this was the largest mock-up they had ever tested in their laboratory, and they had to adjust the receiving structure in order to perform the relevant flanking transmission.”

Strong long-term partnerships make innovation possible

The successful testing of our mock-up represents a major step forward. It is proof that our DfM-oriented aluminium façade system is suitable for unique, challenging projects such as Separatorn 1.

Reaching this point has only been possible thanks to trust-based relationships and a shared commitment to building long-term partnerships.

Skanska, General Contractors on the Separatorn 1 project, have partnered with us on a number of major projects in Sweden. Our most notable recent collaborations include the Stockholm New building, Prisma in Helsingborg, and Gothenburg City Gate. We are delighted that Skanska backed us in pioneering our new aluminium façade system on Separatorn 1. Likewise, end client Fabege AB has demonstrated an open and positive attitude towards innovation on this project and others. Another project we are collaborating on, Textiltorget, features the first use of our next-generation Hybrid Unitised façade.

The trust our partners are putting in us to deliver new solutions is essential in turning these innovations into commonly-used parts of our industry. It creates an opportunity for our R&D and design teams to put years of work into practice on real projects, and encourages us to continue pushing the boundaries.

Next steps with our new façade system and R&D projects

With testing completed, production for the Separatorn 1 project is planned for early July, and installation is set to start later in 2023.

We then hope to use our new aluminium façade system in many more projects, with DfM becoming a key feature of our value chain.

With our new, next-generation HUF also recently deployed for the first time, we are seeing years of R&D activity bear fruit. These projects demonstrate that we can create innovative solutions that work in practice as well as in theory. Their success will give us further motivation and confidence as our R&D activity continues to gather momentum.

This year we will conduct further work on manufacturing for disassembly. DfM goes hand in hand with design for disassembly, which increases the opportunity for material take back at end of life, a topic Staticus has been closely focused on recently (last year, we conducted a façade disassembly exercise together with Dutch façade consultants Frontwise).

We will also complete the construction of our own testing rig this year, and will continue our research into IoT sensors in our next generation HUF.